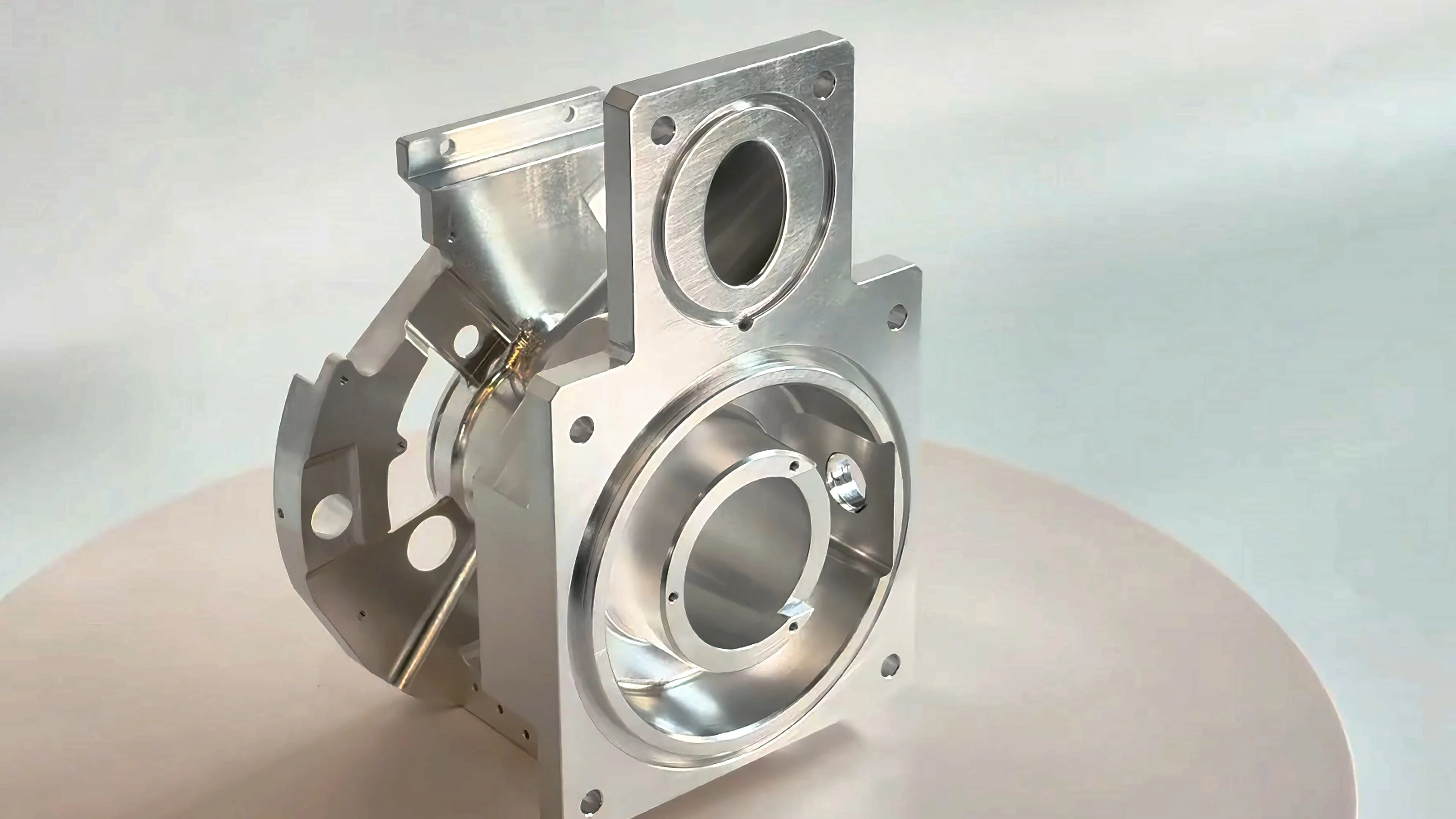

Core Component of Mass Spectrometer: Vacuum Interface Chamber

Material of the vacuum interface chamber

High-quality 6061-T6 aluminum alloy is selected. It has the advantages of both high strength and light weight, with high tensile strength, which can ensure structural stability under complex working conditions. Meanwhile, it has good corrosion resistance, suitable for various industrial environments such as scientific research experiments and electronic manufacturing, meeting the strict performance requirements of vacuum systems for materials.

Processing technology of the vacuum interface chamber

Precision machining requirements for the vacuum interface chamber

- Dimensions and tolerances: Strictly control dimensional tolerances and form and position tolerances, and the roughness must meet the requirements of the drawings (for example, the surface with a roughness of 1.6 is not allowed to be polished manually and must be formed by milling);

- Detail processing: Details such as threads and chamfers must be refined, and the surface must not be scratched during tapping and deburring;

- Surface quality: Natural color conductive oxidation must have uniform color and no color difference to improve wear resistance and corrosion resistance;

- Quality control links: Each process requires first inspection and in-process inspection, and for batch parts, inspection records must be filled in according to standards to ensure product qualification.

Role of the vacuum interface chamber in mass spectrometers

As a core component of the mass spectrometer, its main role is to provide a key connection for the vacuum system. Through its precise interface structure, it ensures the stable construction and maintenance of the vacuum environment, realizing vacuum connection and transmission functions under harsh working conditions. It is a core precision component for the equipment to achieve vacuum functions, which can reduce the risk of system operation failures and help improve the reliability and efficiency of the entire mass spectrometer.

FAQ