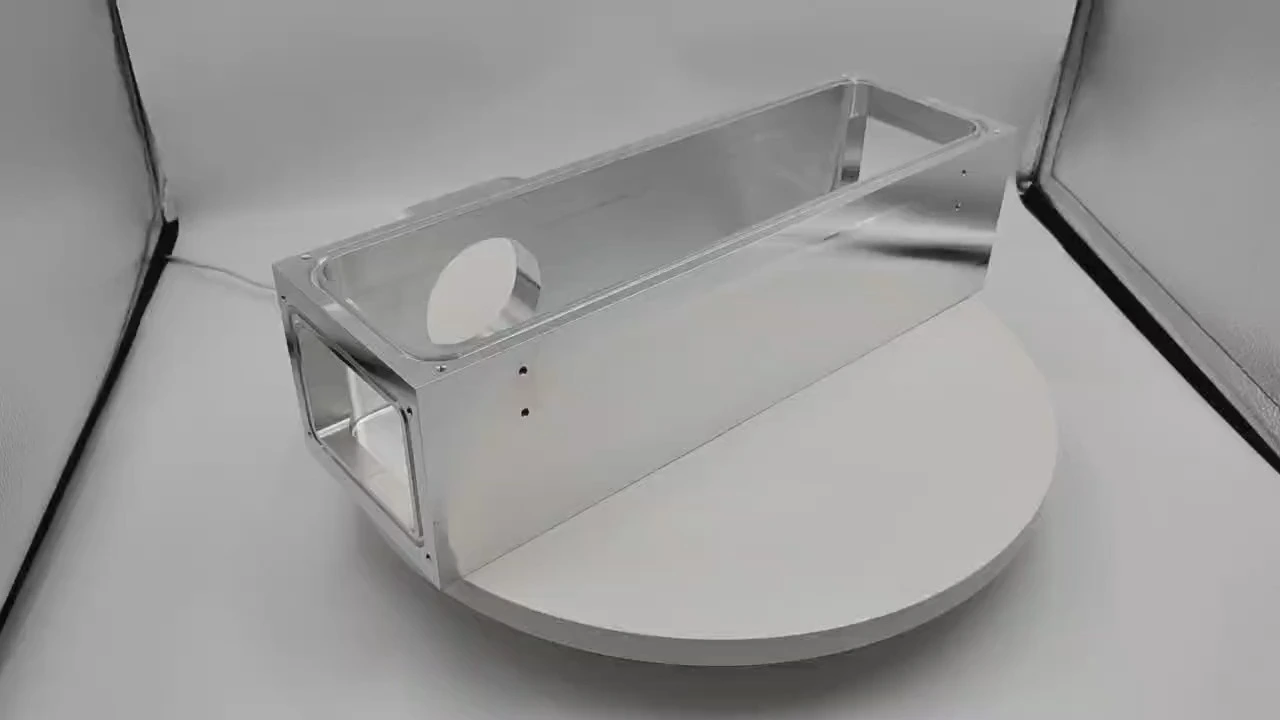

mass spectrometer detector Aluminum processing Aluminum vacuum chamber

Sealing parts are usually made of high-quality seals, sealants or welding.

The selected material should have good vacuum compatibility, low outgassing rate, can withstand the pressure difference in the vacuum environment, and have certain corrosion resistance and high temperature resistance.

The internal and external surface area of the cavity need to be treated in order to reduce the ability of surface adsorption of gas and impurities, reduce the outgassing rate and improve the stability of vacuum.

5.0

Technical requirements:

The design of vacuum chamber needs to consider many factors, such as sealing, strength, thermal stability against short circuit, surface roughness and internal cleanliness. They vary in shape and size, depending on the specific application requirements, and may be cylindrical, square, or other special shapes. On the surface of the chamber, there may be various interfaces and ports for connecting vacuum pumps, measuring instruments, pipes, and other related equipment.

Material:

Aluminium metal

Application areas:

Vacuum chamber can effectively eliminate gas molecules and provide a highly pure and stable vacuum environment, which is widely used in scientific research, semiconductor manufacturing, optical coating, vacuum drying and many other fields.

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Contact person: Mr. Mew

Tel: 86-010-64386101

Email: Info@3wmachina.com

WhatsApp: 86 16046263015

Company address: #10 Ge Daizi Middle Street, Lisui Town, Shunyi District, Beijing China