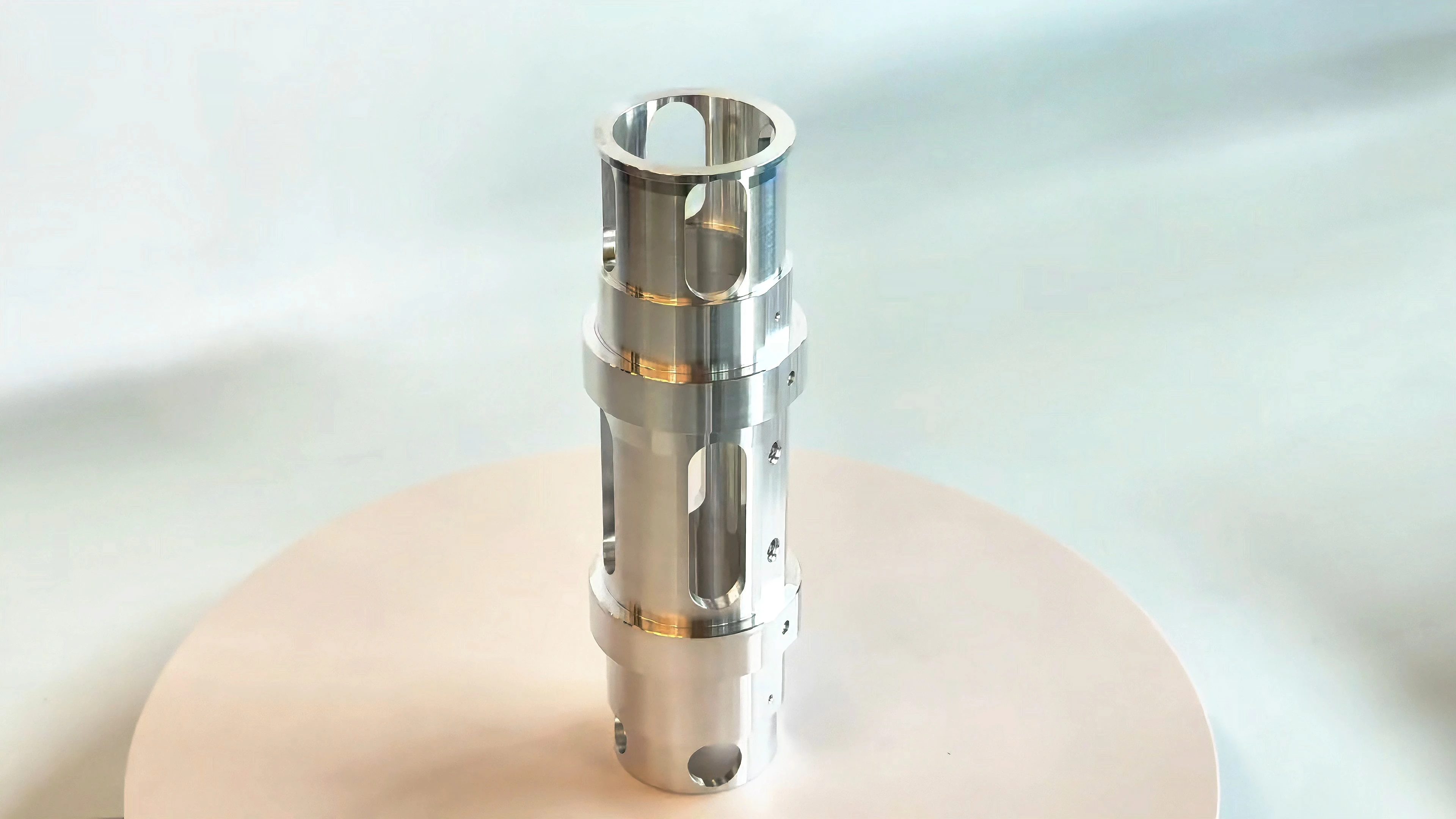

Quadrupole fixed cylinder

Material Selection

6061 alloy is selected, which has good strength, toughness and machinability, and can meet the material requirements of precision instruments for components; the initial raw material is 6061 alloy bar, which lays a material foundation for subsequent processing and ensures the adaptation of strength and machinability.

Processing Technology

Multiple precision processing technologies are adopted, with the core including turn-milling compound technology (for shape processing, feature refinement and tolerance control), CNC processing technology (for key hole forming to ensure position accuracy), and fitter technology (for thread tapping and deburring). Each technology specifies equipment, parameters and quality requirements to ensure processing accuracy.

Processing Steps

- Material preparation: Prepare 6061 alloy bars;

- First turn-milling compound: Conduct rough machining of external dimensions and deburring, control cylinder runout ≤ 0.02mm, mill the 37×60.2mm end face and ensure tolerance;

- Second turn-milling compound: Refine features such as planes and hole systems, control flatness and hole position tolerance, deburr and remove oxide scale;

- CNC processing: Complete the forming of M5×1 counterbore;

- Fitter work: Conduct M3×1 and M4 thread tapping, and perform secondary deburring;

- Quality inspection: Based on the process card (recording process time, operator and inspection information), control the quality through the inspection link to ensure compliance with design requirements.

Application Areas

It is mainly used in precision analytical instruments equipped with quadrupole rod structures (such as mass spectrometers) to provide a stable installation foundation for quadrupole rod components; it is widely applicable to fields relying on precision instrument detection, such as environmental monitoring (e.g., pollutant composition analysis), biomedicine (e.g., drug component detection), and material analysis (e.g., element and component identification), ensuring the reliable operation of equipment and the realization of accurate detection and analysis functions.

FAQ