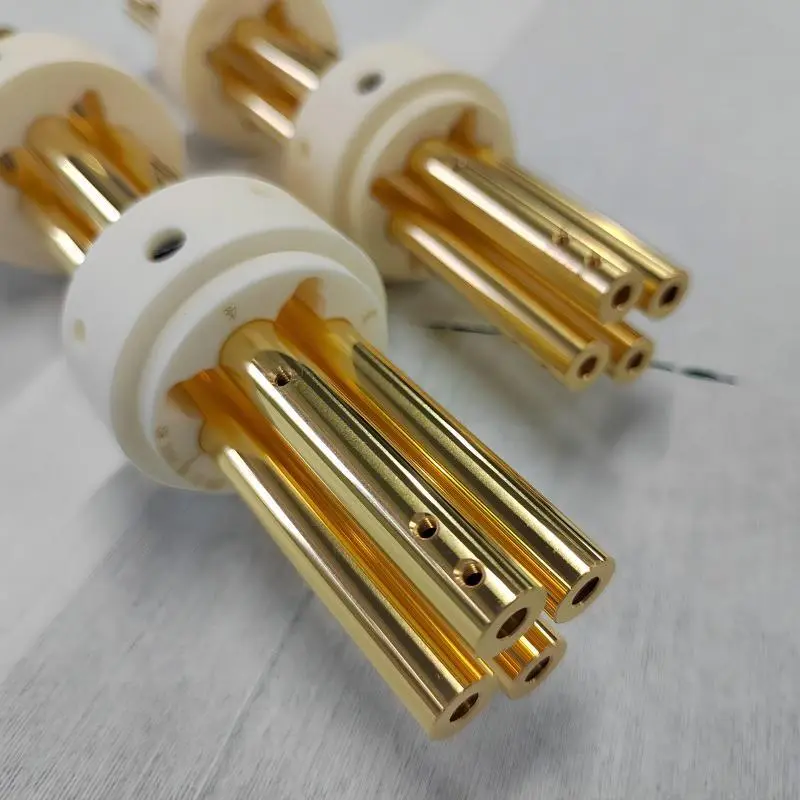

Customised Quadrupole Design Electrode Rod and Ceramic Materials

The 3W machine standard quadrupole has proven to be a very cost effective solution for use in the proofing and prototyping stages of our customers’ designs and for use in lower volume instrument production. All of our quadrupoles are supplied cleaned, assembled in our laminar flow cleanroom, with mechanical test results, showing the maximum measured deviation between opposing rods.

5.0

Technical requirements:

Our manufacturing processes are primarily based around electrode rods of 12mm diameter, up to 200mm in length, dimensions and features of which can be produced to precisions of 20 parts per million. We also have the capability to manufacture electrode rods in diameters from 6mm to 12mm. To complement this, the mechanical dimensions of the parts and assemblies can be determined down to hundredths of a micron, using 3W machine unique test equipment.

Material:

Electrode rods are manufactured from molybdenum. Our standard range of collars are manufactured in high purity grade alumina ceramic.

Application areas:

Our ability to optimise the design in terms of cost and performance can help reduce our customers’ time-to-market on new instrument designs, or indeed help to identify potential performance issues with existing instrument designs.Electrode rods can also be manufactured from a variety of different materials including stainless steel.

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Contact person: Mr. Mew

Tel: 86-010-64386101

Email: Info@3wmachina.com

WhatsApp: 86 16046263015

Company address: #10 Ge Daizi Middle Street, Lisui Town, Shunyi District, Beijing China