Gas detector Quadrupole mass analyzer -3W MACHINE

The mini rod has a high resolution and sensitivity, which can accurately distinguish ions with small mass differences, and the detection effect of trace substances is excellent; its small design not only saves space but also effectively shortens the ion flight path, reduces ion diffusion and loss, greatly improves the detection speed and accuracy, and makes the gas phase detector widely used in environmental monitoring, food safety, drug research and development and other fields, and provides reliable data support.

The principle of structure

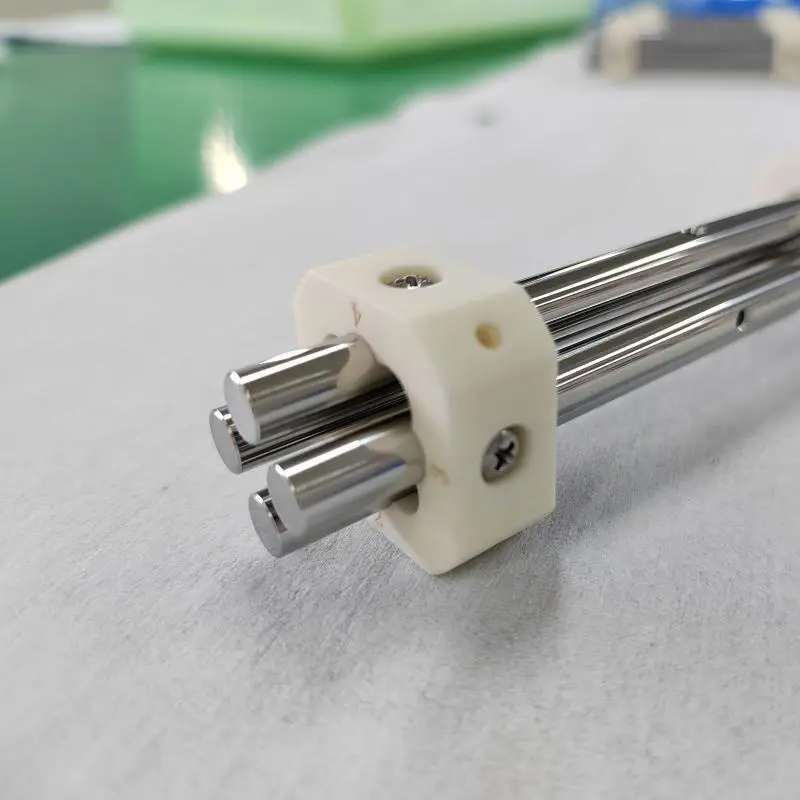

The tetrapole mass analyzer mini rod consists of four parallel poles. A variable electric field is formed by applying specific DC and RF voltages to the pole. Ions with different mass-to-load ratios move on a specific trajectory in an electric field because of different pressures, and the specific mass-to/load ratio ions steadily pass through to the detector, thereby separating the different ions in the detection gas and achieving substance composition analysis.

Performance characteristics

The minibar has a high resolution, can distinguish ions with small differences in mass, and can detect complex mixtures with precision. Its sensitivity is high and it can detect trace substances. The response speed is fast and the detection analysis can be completed in a short time. The stability is strong, and the long working time can still ensure the accuracy of the data, providing reliable and efficient testing support for scientific research, quality inspection and other work.

The difficulty of processing

The precision requirement during machining is extremely high, and the linearity and cylindricality error of the rod must be extremely small. The tolerance of size of the electrodes is strictly limited to the order of micrometers. We can guarantee the uniformity of the four poles. The materials should be conductive and corrosion-resistant.

◎ Reliable

◎ efficient

◎ accurate data

FAQ