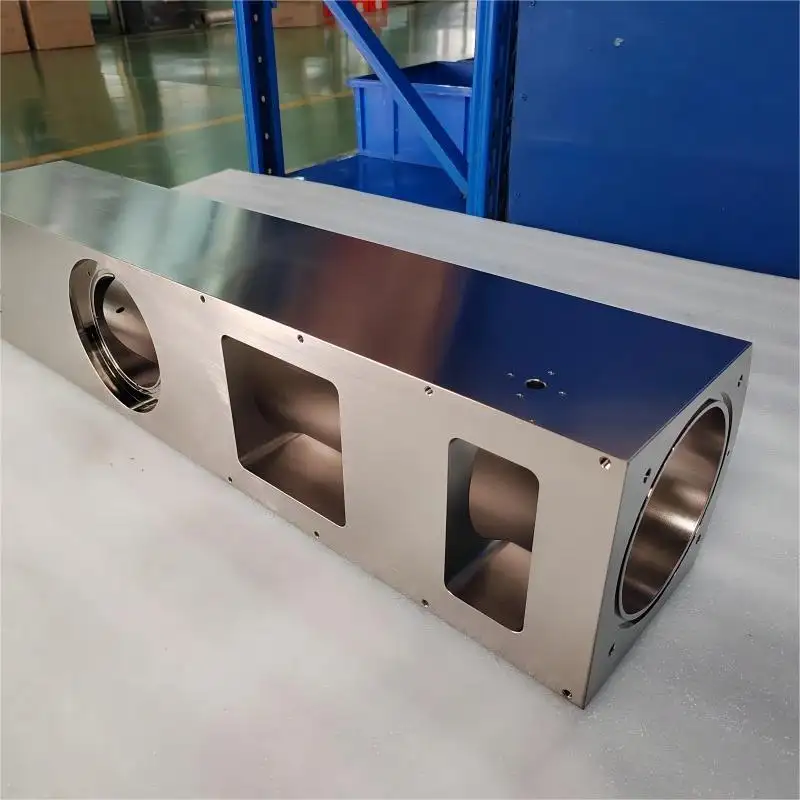

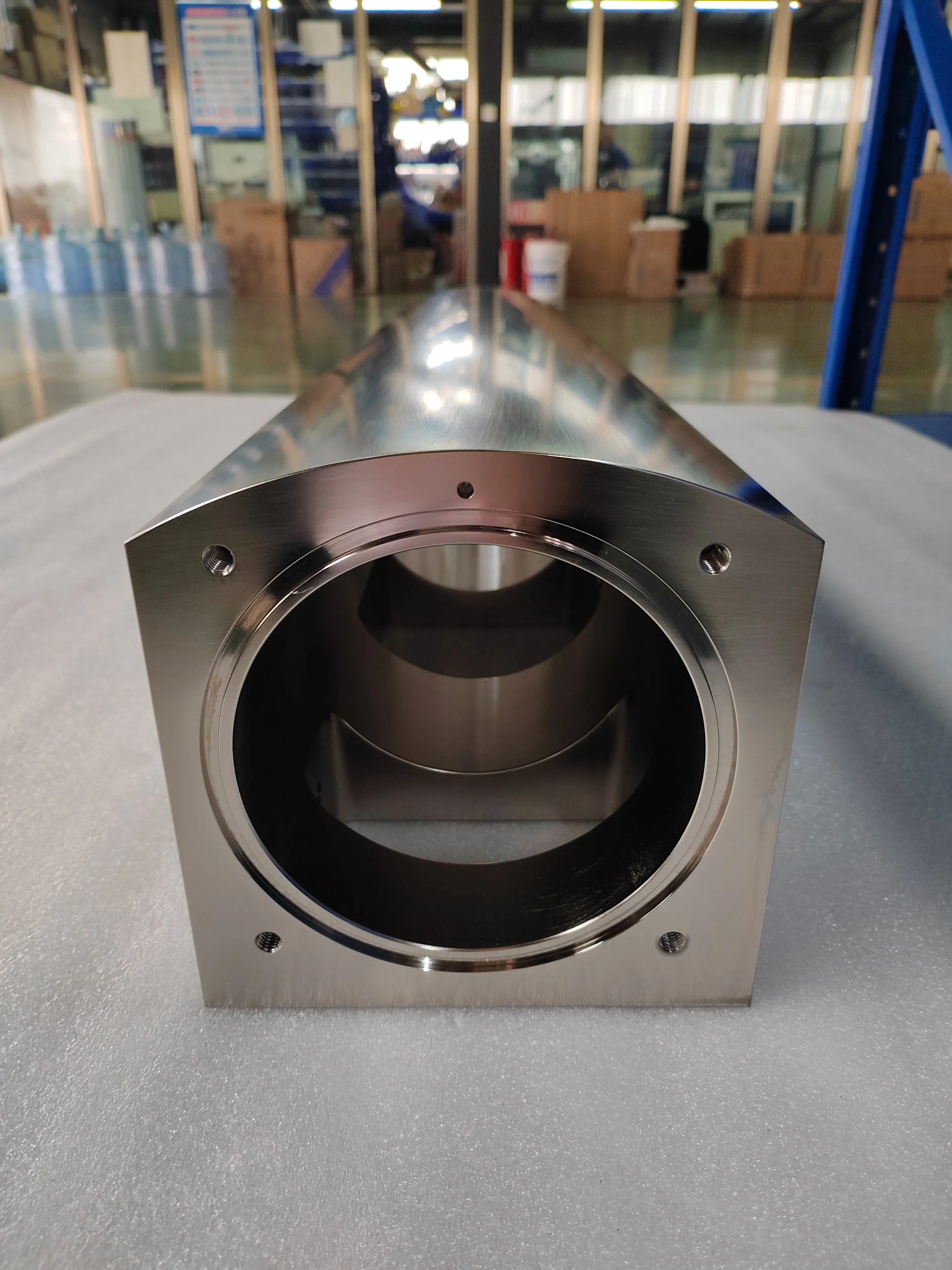

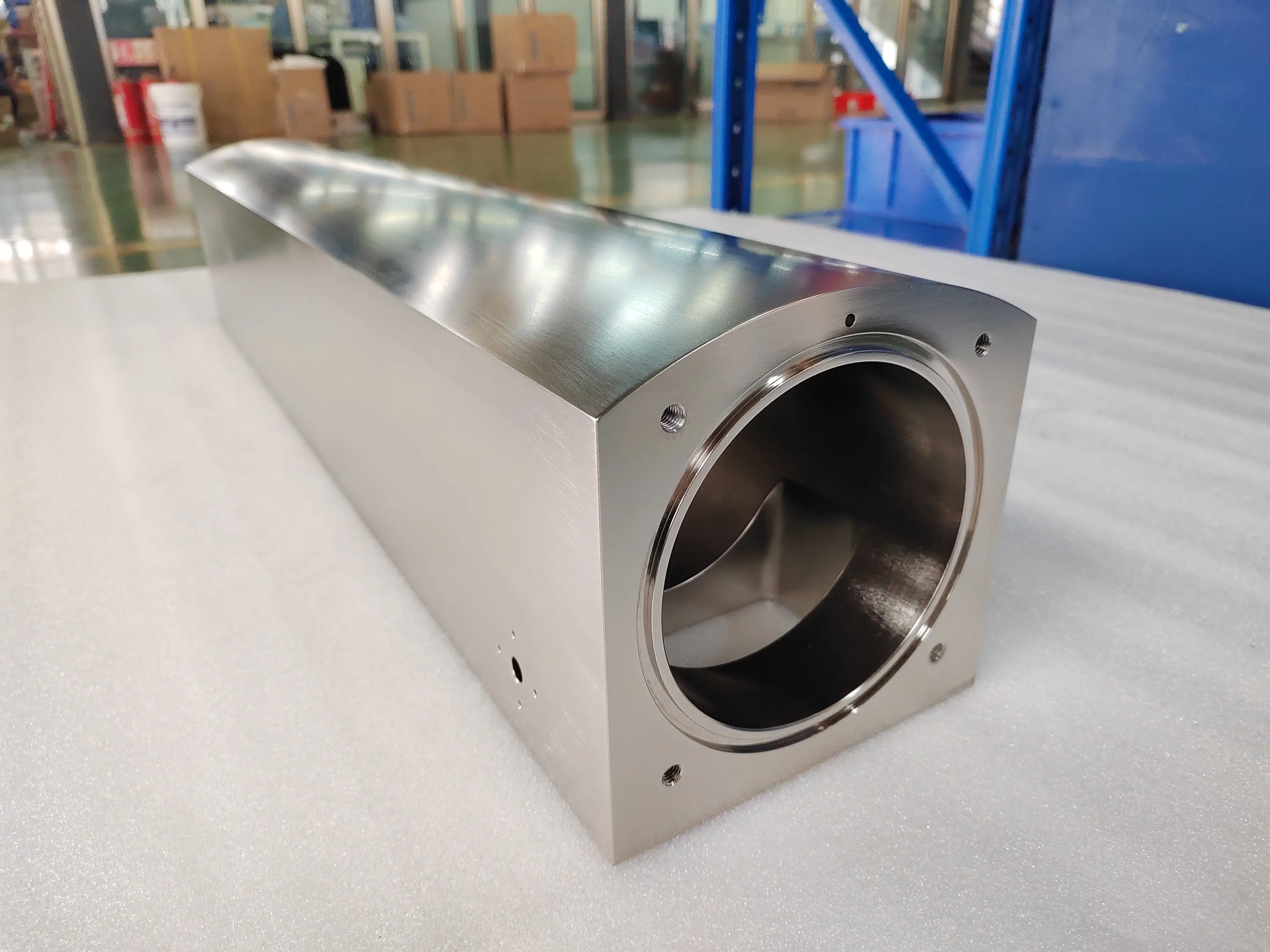

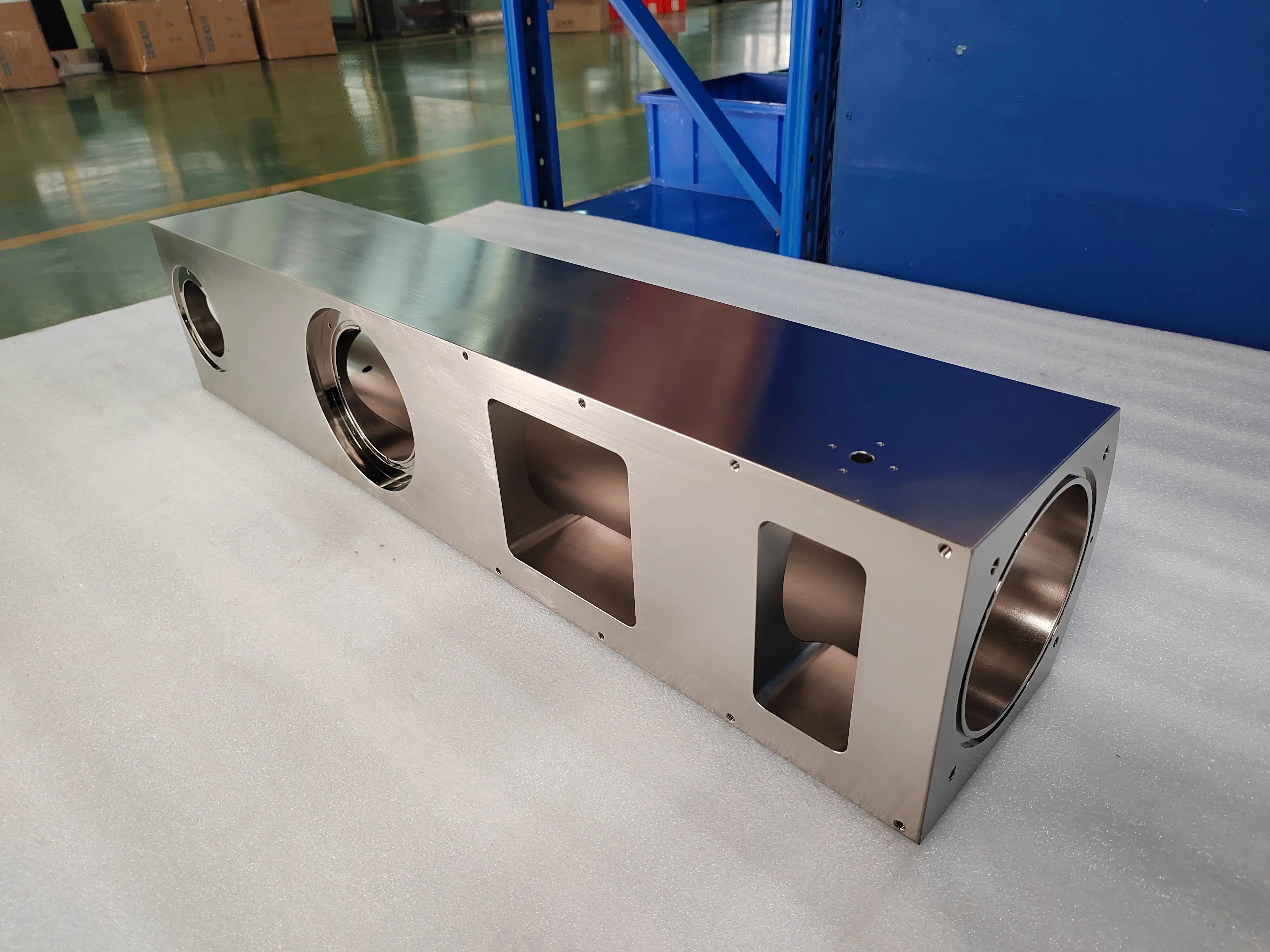

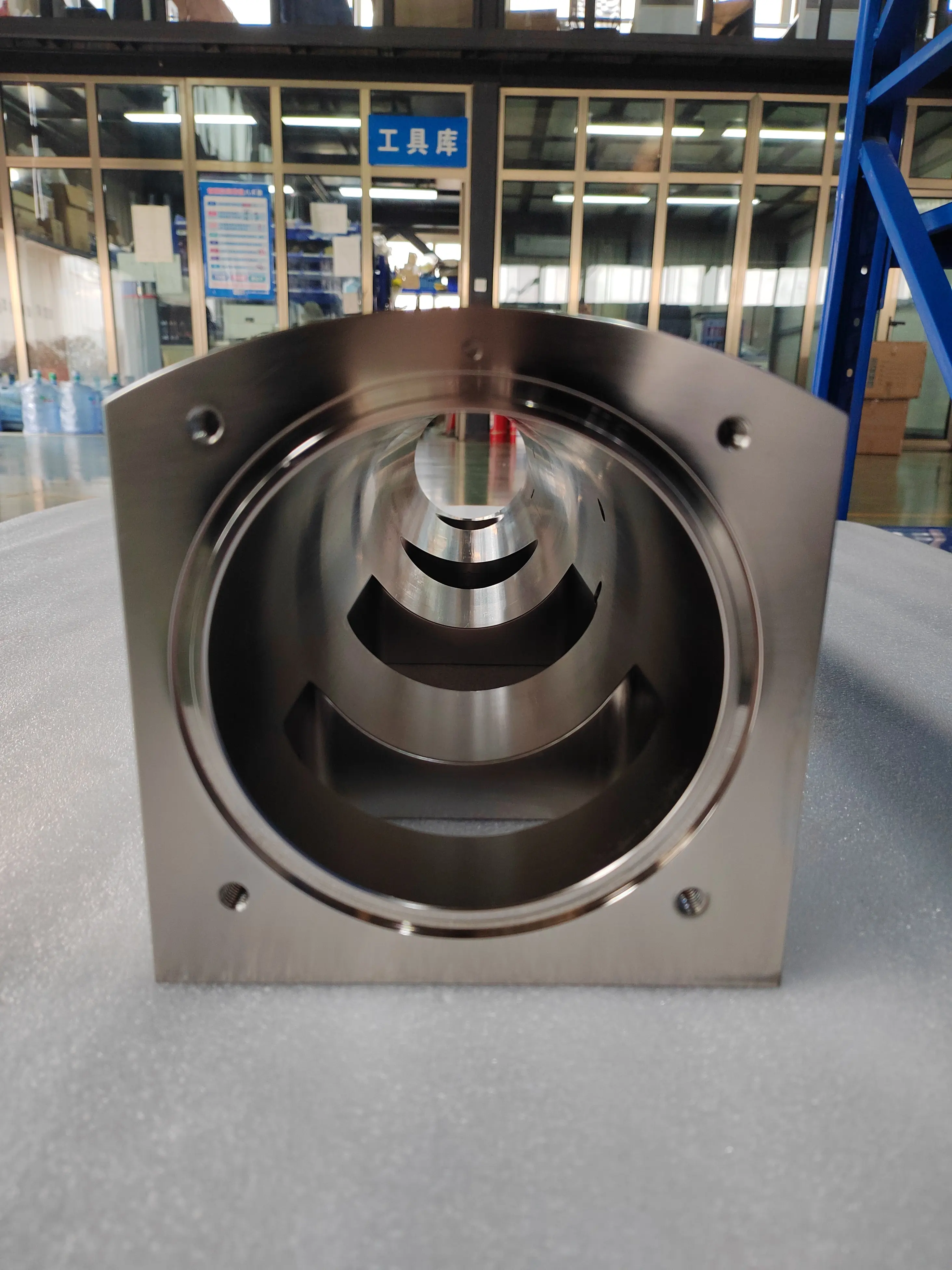

High Precision Parts ODM for Electronics and Have Certain Corrosion Resistance and High Temperature Resistance. the Internal and External Surface Area of the Cavity Need to Be Treated in order to Reduce the Ability of Surface Adsorption of Gas and Impurities

Product details of the high precision parts

Product Description

The raw material of 3W MACHINE high precision parts meets the requirements of overseas technology. This product features easy usage and best performance. The product is deeply remembered mainly because of its outstanding features.

Company Feature

• 3W MACHINE enjoys traffic convenience due to the superior geographical conditions. We also have complete supporting facilities nearby.

• 3W MACHINE takes a proactive approach to 'Internet +' thinking in the business management. We combine E-commerce with offline franchise business mode, which contributes to the annual increment of sales volume and increasingly wide sales range.

• Founded in 3W MACHINE developed the business based on large-scale production after years of laborious exploration.

• Our company attaches great importance to the talents cultivation. Therefore, we have created a talent team with rich industry experience in technology, management, sales and operation.

3W MACHINE is a manufacturer specializing in the production of Mechanical Engineering Parts,CNC Turning Parts,CNC Milling Parts,Rapid Prototype Machined Parts,aluminum parts,stainless steel parts,plastic parts,Cast aluminum parts,Cast steel parts,Stamping Molds,Injection mould,Die Casting Molds. The products are cost-effective with high quality and favorable price. Feel free to call us for consulting or business talk.