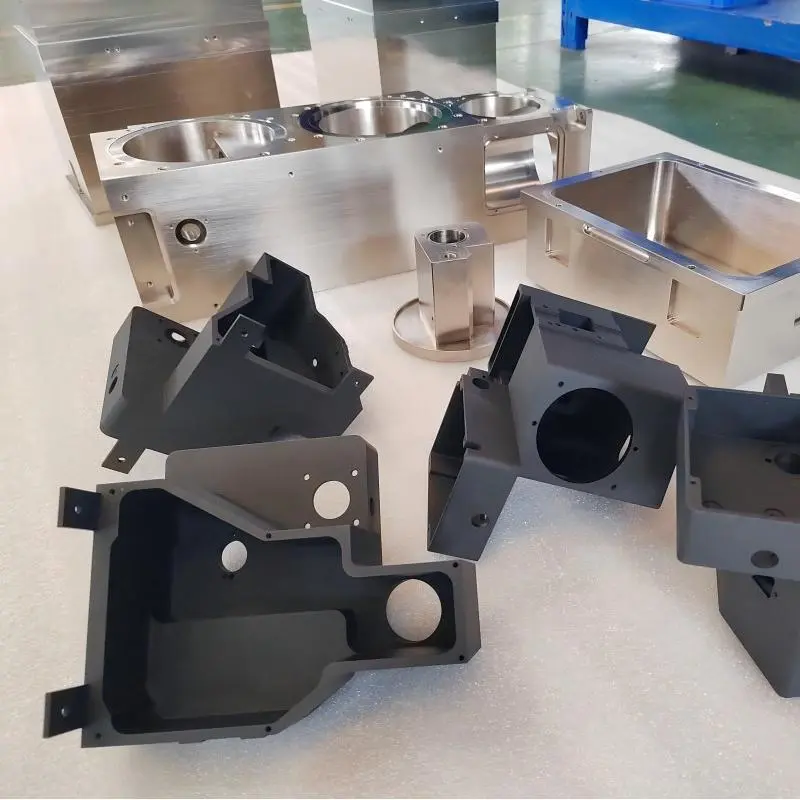

Equipment and instruments, milling parts, surface treatment, black oxidation-3W MACHINE

This is a special-shaped parts of an instrument, processing materials using metal aluminum 6061, through the DMG five axis rough processing, heat treatment, time effect treatment, the final finishing, surface blackening treatment, the completion of processing.

Regarding the selection of scientific instrument parts

For scientific instrument parts, especially this kind of irregular shape that is difficult to process, in addition to having processing performance, the most important thing is the stable performance of long-term use, to ensure that the parts do not deform after temperature difference changes, thus improving the overall performance of the equipment, so the metal aluminum, 6 series, 6061, after heat treatment and aging processing, is very stable, especially suitable for scientific equipment and instruments.

Guarantee the tolerance requirements for non-standard processing.

This part not only has different shapes, but also requires high cooperation between parts, strict tolerances, and uses a five-axis machine tool from DMG for multi-faceted processing to avoid errors caused by multiple clamping.

Surface treatment Blackening

Chemical blackening is a commonly used method. The parts are placed in a specific blackening solution, and the chemical substances in the solution react with the metal surface of the parts. Under the control of suitable temperature, time, and other conditions, a black oxide film gradually forms. The composition and process parameters of the blackening solution will be different for different metal materials.

◎ Attractive

◎ corrosion-resistant

◎ long-lasting

FAQ