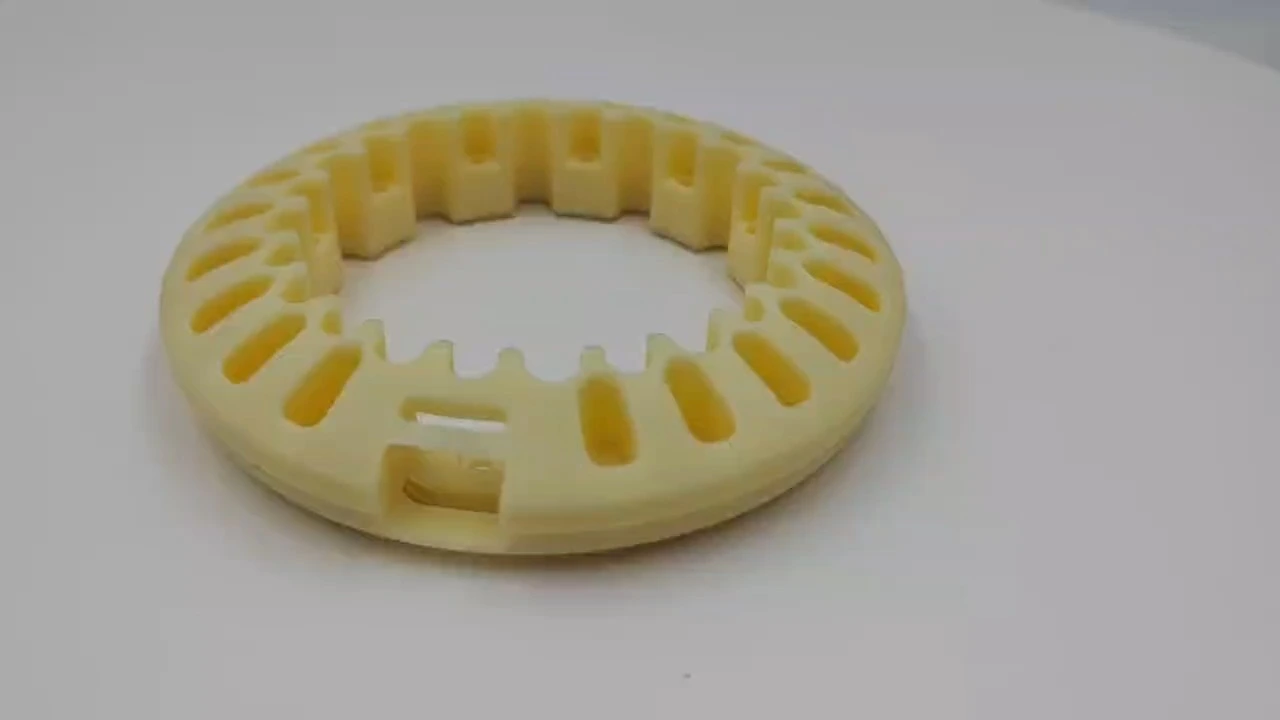

Custom Processing CNC machining Customize Seat ring

Using high-quality nylon material, with high strength, wear resistance, chemical corrosion resistance, self-lubricating and other excellent performance. The low water absorption of nylon allows it to maintain dimensional stability in different environments, ensuring the accuracy and reliability of parts.

Through advanced CNC numerical control machining techniques, each part is precisely cut and molded to achieve extremely high dimensional accuracy and surface finish. Complex shapes and fine structures are perfectly realized to meet the most stringent design requirements.

5.0

Technical requirements:

Its design has been carefully considered, giving full play to the advantages of nylon materials, while combining the actual application requirements, optimizing the structure to achieve lightweight, high strength and good assembly performance. We provide customized production services, according to the specific needs of customers, adjust the size, shape, hole location and other parameters, to create a unique component solution for you.

Material:

nylon

Application areas:

Applicable to many fields, such as medical equipment, electronic instruments, automatic machinery and so on. In medical equipment, it can provide a comfortable and safe grip for hand-held instruments; In electronic instruments, it can play a good role in insulation and shock absorption; In automated machinery, to ensure the smooth operation and precise fit between components.

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

Just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Contact person: Mr. Mew

Tel: 86-010-64386101

Email: Info@3wmachina.com

WhatsApp: 86 16046263015

Company address: #10 Ge Daizi Middle Street, Lisui Town, Shunyi District, Beijing China